Allot of times in industrial environments we get noise on the analog signal input to PLC's or other controllers. The noise can be generated by motors, bad wiring, etc.

Placing a 1- 100 uF capacitor on the input signal and ground (common to the cabinet) will reduce the noise that the input is receiving.

If you have any questions, or need further information please contact me.

Thank you,

Garry

Practical tips and techniques for automation control tasks. We will answer questions and provide sample programming solutions.

Showing posts with label analog. Show all posts

Showing posts with label analog. Show all posts

Thursday, August 28, 2014

Sunday, August 24, 2014

Here’s a Quick Way to Understand PLC Inputs and Outputs

The term I/O means Input/Output. I/O can come in two different types; Discrete or Analog

Most people starting out leaning about programmable logic controls (PLC) are taught all about discrete input and outputs. Data is received from devices such as push-buttons, limit-switches etc. and devices are turned on such as motor contactor, lights, etc. Discrete input and output bits are either on or off. (1 or 0)

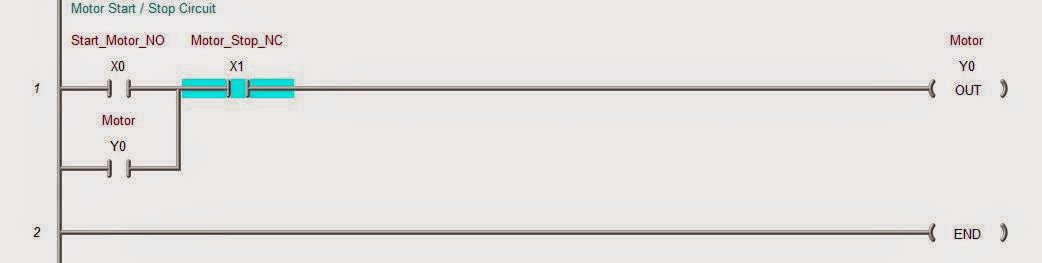

The following program will show a motor control circuit stop start.

Motor off:

Motor on:

Analog inputs

Common input variables for analog are temperature, flow, pressure, etc. They are converted to an electrical signal into a PLC analog input. Standard electrical signals are 0 - 20 mA, 4 - 20 mA, 0 - 10 volts DC, -10 - 10 volts DC.

Note: It is recommended that a 4 - 20 mA signal is best. If voltage is required, a resistor can be added to get a voltage input.

Analog outputs

Common output variables for analog are speed, flow, pressure, etc. They are converted from a word in the PLC to the output of the analog. The range of signal is then outputted to the device to control the position, rate, etc. Standard electrical signals to the device are 4 - 20 mA, 0 - 10 volts DC, -10 - 10 volts DC.

Both Analog Inputs and Outputs use words to determine the signal going to or from the device.

Example: 4 - 20 mA current Input - 8 bit resolution

4 mA = 000000002 = 0016

20 mA = 111111112 = FF16

Example: 4 - 20 mA current Output - 8 bit resolution

0016 = 000000002 = 4 mA

FF16 = 111111112 =20 mA

For a review of numbering systems, follow the link below:

What everyone should know about PLC numbering systems

Let me know if you have any questions or need further information.

Most people starting out leaning about programmable logic controls (PLC) are taught all about discrete input and outputs. Data is received from devices such as push-buttons, limit-switches etc. and devices are turned on such as motor contactor, lights, etc. Discrete input and output bits are either on or off. (1 or 0)

The following program will show a motor control circuit stop start.

Motor off:

Motor on:

Analog inputs

Common input variables for analog are temperature, flow, pressure, etc. They are converted to an electrical signal into a PLC analog input. Standard electrical signals are 0 - 20 mA, 4 - 20 mA, 0 - 10 volts DC, -10 - 10 volts DC.

Note: It is recommended that a 4 - 20 mA signal is best. If voltage is required, a resistor can be added to get a voltage input.

Analog outputs

Common output variables for analog are speed, flow, pressure, etc. They are converted from a word in the PLC to the output of the analog. The range of signal is then outputted to the device to control the position, rate, etc. Standard electrical signals to the device are 4 - 20 mA, 0 - 10 volts DC, -10 - 10 volts DC.

Both Analog Inputs and Outputs use words to determine the signal going to or from the device.

Example: 4 - 20 mA current Input - 8 bit resolution

4 mA = 000000002 = 0016

20 mA = 111111112 = FF16

Example: 4 - 20 mA current Output - 8 bit resolution

0016 = 000000002 = 4 mA

FF16 = 111111112 =20 mA

For a review of numbering systems, follow the link below:

What everyone should know about PLC numbering systems

Subscribe to:

Posts (Atom)